crusherjaw

.jpg)

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

The main fields of application for a jaw crusher include building materials, mineralogy and metallurgy, ceramics and glass, materials science and environmental analysis They BB 50 是 RETSCH 颚式破碎机系列的最小型号,专为实验室样品制备而设计。 创建PDF

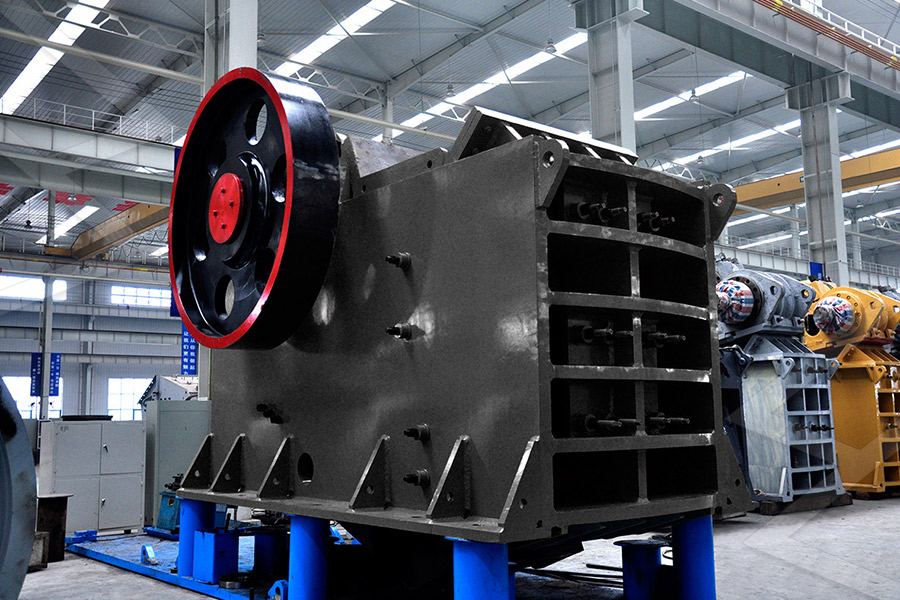

CJ409 颚式破碎机

CJ409 颚式破碎机 Feed opening 895 x 660 mm (35 x 28 in) mm Motor power 75 kW (100 hp)It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is under jaw crusher 百度百科

颚式破碎机 实验室破碎机 金木石实验室科技

金木石科技的DJ和DJC系列实验室颚式破碎机具备结构简单、操作方便、耐磨性能优越等特点,能够轻松应对各种硬度的固体物质,可用于实验室大批量或连续作业,可满足分析 2019年4月25日 As a leading Jaw Crusher manufacturer in China, GATOR is committed to various jaw crushers and screening equipment design, manufacturing and sales, The jaw GATOR singleCrusherJaw Crusher

Jaw Crusher an overview ScienceDirect Topics

Failure analysis of a crusher jaw John O Olawale, Simeon A Ibitoye, in Handbook of Materials Failure Analysis, 2018 5 Conclusion 1 The locally produced crusher jaws failed thyssenkrupp jaw crusher Experience the next frontier of engineering jaw crushers guided by thyssenkrupp Polysius's solutions and servicesthyssenkrupp jaw crusher thyssenkrupp Polysius

Jaw Crusher SpringerLink

2023年6月21日 Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable The movable jaw plate approaches the fixed jaw plate It features the reliable and highly productive Sandvik CJ411 jaw crusher and comes complete with feeder motors, starters, frequency drive and an electrical control panel to Sandvik CJ411 SingleToggle Jaw Crusher For High Production

Jaw Crushers Heavy Duty Finlay

2024年7月5日 Jaw Crushers Finlay® tracked Mobile Jaw Crushers are renown for their capabilities in the reduction and sizing of aggregates for construction materials and also recycling construction waste The Finlay range of Jaw Crushers are designed to meet the toughest demands of primary crushing applications with their impressive power, reliability CJ409 颚式破碎机 Feed opening 895 x 660 mm (35 x 28 in) mm Motor power 75 kW (100 hp)CJ409 颚式破碎机

.jpg)

Jaw Crushers high quality and reliability from RETSCH

Retsch Products Milling Jaw Crushers The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and precrushing of mediumhard, hard, brittle and tough materials The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants Benchtop Unit® C Series™ jaw crushers are used as primary crushers in aggregates production, mining operations and recycling applications® C Series™ jaw crushers

Jaw Crusher Wear Parts Columbia Steel Cast Products LLC

Columbia Steel manufactures the world's largest number of jaw designs Wear parts for all popular jaw crushers, include: jaw dies, cheek plates, and more2023年2月16日 Jaw plates are the parts of the jaw crusher that direct contact with the material being crushed They are rectangular in shape and are designed to fit around the crushing chamber of the jaw crusher Jaw plates come in pairs and are positioned opposite each other, with one jaw plate being fixed and the other being movableJaw Plates: Everything You Should Know Crusher Wear Parts

Industrial Solutions Jaw crushers ThyssenKrupp

2022年11月21日 nce in manufacturing jaw crushersThey are used in mines and quarries as primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on the blasting method, in preparation for finish crushing or conveyingFor these tasks thyssenkrupp Industrial Solutions has in its range two types of jaw crusher, 2021年5月6日 Jaw Crusher Working Principle A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge pointJaw Crusher Working Principle 911 Metallurgist

Jaw crusher EB

Consistent crushing at high throughputs – our Jaw Crusher EB is the solution for crushing mediumhard to very hard materialsSandvik QJ341 mobile jaw crusher is the ideal solution for a wide range of applications Equipped with a C12 jaw crusher, a powerful and fuelefficient engine, it is designed to tackle the most difficult operations QJ341 Features Product data Images Additional product information Case stories Our tracked jaw crushers Request a quoteSandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher

JAW PLATES Precision Casting

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time A set 2024年2月5日 Discover how does a jaw crusher work with our simple guide Learn about the mechanics and operation of jaw crushers on our blogHow Does a Jaw Crusher Work? A Simple Guide JXSC

How Does a Jaw Crusher Work Jaw Crusher

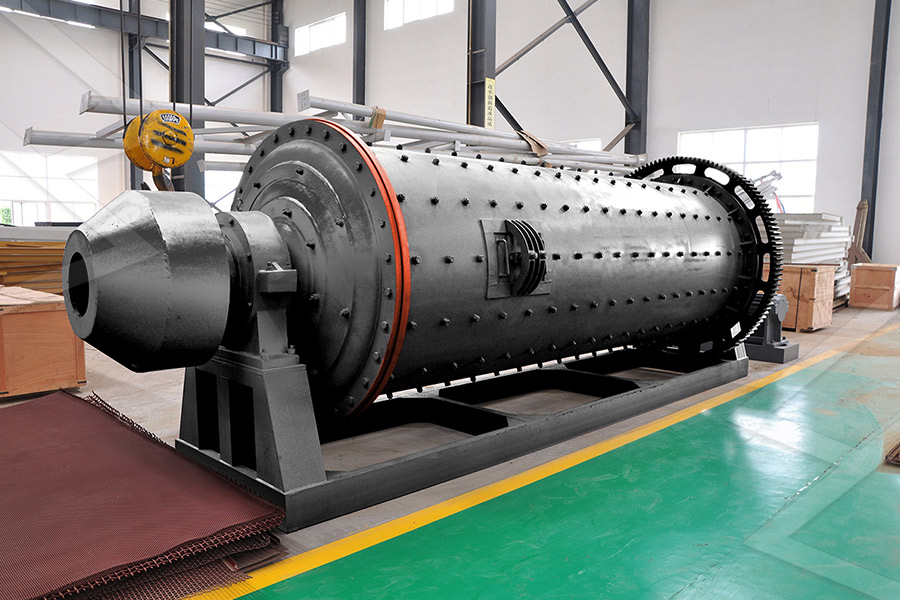

2 天之前 A jaw crusher is an important piece of machinery that helps break aggregate material down into the right size Learn more about this machine on our blog todayJaw Crusher In Mineral Processing Design and Operations (Second Edition), 2016 44 Jaw Crusher Capacity Estimation The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing Jaw Crusher an overview ScienceDirect Topics

.jpg)

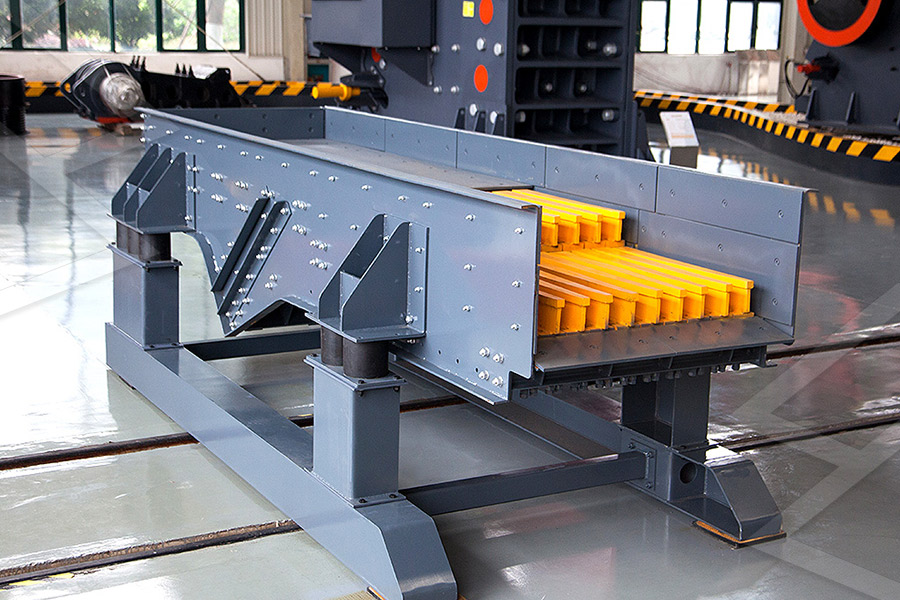

Jaw Crusher: Range, Working Principle, Application

2022年2月22日 Jaw Crusher Features Based on principle of crushing without rubbing Minimum dust Oil lubrication, Law wear parts Gap adjustment and overload protection High capacity, High operational eliability Long service and life time Easy replacement of wear and spare part Wide range of applicationDescription: Jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling Mt Baker Mining and Metals’ jaw crushers are industrial grade, continuous duty machines They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a Jaw Crushers Mt Baker Mining and Metals

.jpg)

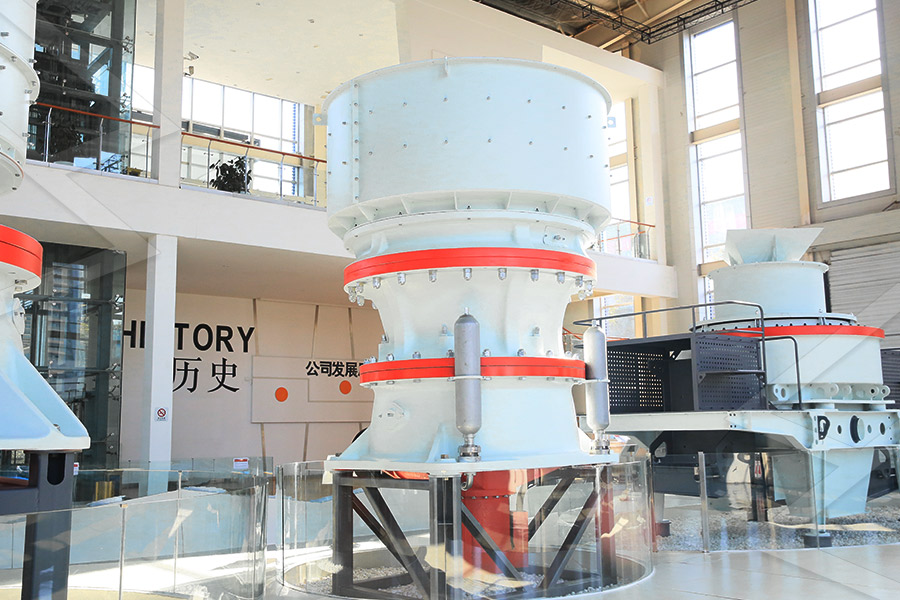

China Jaw Crusher Manufacturer, Impact Crusher, Cone

China Jaw Crusher Supplier, Impact Crusher, Cone Crusher Manufacturers/ Suppliers Jiangsu Zhongyou Machinery Co, Ltd2022年12月22日 the same key characteristics as the standard model These include hydraulic adjustment, reversible jaw and hydraulic drive to enable the crusher to start under load, thereby minimizing downtime Additional features of the QJ341+ include a telescopic natural fines conveyor with an increased discharge height and a three position bypass TECHNICAL SPECIFICATIONS SANDVIK QJ341+ JAW

Jaw Crushers

2024年7月4日 jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industriesSandvik crushing and screening equipment Unrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction applicationsRock Crushers, Stone Crushers, Screening and Crushing

.jpg)

Jaw Crushers Heavy Duty Finlay

2024年7月5日 Jaw Crushers Finlay® tracked Mobile Jaw Crushers are renown for their capabilities in the reduction and sizing of aggregates for construction materials and also recycling construction waste The Finlay range of Jaw Crushers are designed to meet the toughest demands of primary crushing applications with their impressive power, reliability CJ409 颚式破碎机 Feed opening 895 x 660 mm (35 x 28 in) mm Motor power 75 kW (100 hp)CJ409 颚式破碎机

Jaw Crushers high quality and reliability from RETSCH

Retsch Products Milling Jaw Crushers The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and precrushing of mediumhard, hard, brittle and tough materials The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants Benchtop Unit® C Series™ jaw crushers are used as primary crushers in aggregates production, mining operations and recycling applications® C Series™ jaw crushers

Jaw Crusher Wear Parts Columbia Steel Cast Products LLC

Columbia Steel manufactures the world's largest number of jaw designs Wear parts for all popular jaw crushers, include: jaw dies, cheek plates, and more2023年2月16日 Jaw plates are the parts of the jaw crusher that direct contact with the material being crushed They are rectangular in shape and are designed to fit around the crushing chamber of the jaw crusher Jaw plates come in pairs and are positioned opposite each other, with one jaw plate being fixed and the other being movableJaw Plates: Everything You Should Know Crusher Wear Parts

.jpg)

Industrial Solutions Jaw crushers ThyssenKrupp

2022年11月21日 nce in manufacturing jaw crushersThey are used in mines and quarries as primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on the blasting method, in preparation for finish crushing or conveyingFor these tasks thyssenkrupp Industrial Solutions has in its range two types of jaw crusher, 2021年5月6日 Jaw Crusher Working Principle A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge pointJaw Crusher Working Principle 911 Metallurgist

.jpg)

Jaw crusher EB

Consistent crushing at high throughputs – our Jaw Crusher EB is the solution for crushing mediumhard to very hard materialsSandvik QJ341 mobile jaw crusher is the ideal solution for a wide range of applications Equipped with a C12 jaw crusher, a powerful and fuelefficient engine, it is designed to tackle the most difficult operations QJ341 Features Product data Images Additional product information Case stories Our tracked jaw crushers Request a quoteSandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher